This page is for those of you who have an insatiable appetite for information. We will walk through a typical Brick to Brick installation from start to finish and point out a few things you don’t want to see.

|

|

Here are things to watch out for that we see some other companies doing.

- In an effort to cut costs many companies don’t use a vinyl brick mold on the exterior, which results in a weaker window. They will use wood filler and cap it with aluminum which doesn’t usually match the colour of the window. This shouldn’t be referred to as a brick to brick installation.

- Thermoplastic caulking should be used as it won’t crack over time and can be cleaned easily. It forms a flexible seal, has exceptional adhesion, resists moisture and has weathering capabilities. It is available in many colours.

- Anyone who has seen a shaped window capped with aluminum knows how this can ruin the look of a home.

- If old caulking or paint lines are visible on the exterior then the depth of the window wasn’t measured properly.

- Old header capping is left in place saving time, making the installation look untidy.

- Existing Bay’s can really be made a mess of because most companies don’t have the capabilities to measure properly or manufacture the necessary components . Posts are left in place and capped resulting in a bulky look and much smaller glass area. This is a retrofit installation not brick to brick.

- Some companies use vinyl jambs and casing trim on the interior which can’t be painted or sized properly. Vinyl trim can’t be nailed to the wall and will bow over time and looks cheap. Vinyl jambs don’t add strength to the overall window and will also bow over time.

- Often we see vinyl windows that weren’t sized properly and existing interior shutters or blinds won’t fit back into the opening.

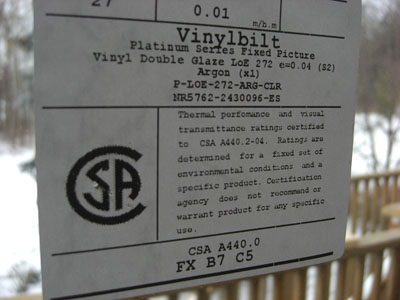

- It’s hard to believe but we still see companies installing inferior products with decades old technology, such as metal spacers between the glass panes and not using Argon gas and LoE coatings.

- Don’t be fooled not all windows are created equally, many companies are installing CSA “Approved” or “Compliant” or “Tested” windows. The best, highest performing windows available are CSA “Certified” and are subject to much more rigorous standards and frequent performance audits.

- Job sites are often left unfinished and untidy.